Power flushing your Central Heating system

It is a proven fact that unless a good quality corrosion and scale inhibitor

has been added to a heating system it will begin to deteriorate from the moment

it becomes operational.

The combination of water, air, mixture of metals and even installation debris

and contaminants can result in internal corrosion, sludge formation and scaling

of boilers and heat exchangers, seriously impairing the efficiency of the heating

system. This leads to higher energy bills and ultimately failure of the pump,

radiator, valves or boiler.

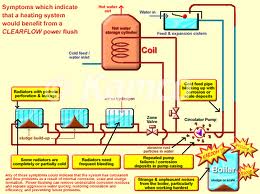

Symptoms of Heating System Corrosion include:

- Cold panels in radiators

- Blocked radiator requiring frequent 'bleeding'

- System slow to warm up

- Noisy boiler

- Long recovery time after drawing off hot water

- An inadequate water supply

- Failure of pumps, radiators or valves

If you recognise any of the above symptoms then your heating system would almost certainly

benefit from Powerflushing.

Powerflushing is a highly effective cleansing operation which works by pumping water at

a much higher velocity than usual through the heating system to loosen and mobilise

harmful corrosive deposits and to suspend them in the rapidly moving water. The process

is made more effective by specialist cleansing chemicals and an instantaneous flow

reversal device which creates turbulence in the radiators to optimise 'pick up' of debris.

Once loosened, the unwanted debris is purged from the system with clean water. At the

end of the flushing process the system contains fresh clean water and reinstatement of

the system to normal operation takes only minutes.

During the process, radiators are individually flushed without removing or disconnecting.

Indeed the whole process is carried out with minimal disturbance and disruption to the

normal operation of the system, often without the need to disconnect the boiler or

radiators.

The operation takes several hours to complete and once the system has been thoroughly

cleansed, the cleaning agent is neutralised and a corrosion inhibitor added to the system.

If you are upgrading your system with a new high efficiency condensing boiler then power

flushing is essential if you want to realise the published energy efficiency levels of

90% - 94%. Your new boiler cannot be expected to fulfil its potential if your heating

system is full of sludge and scale. Modern boilers have much smaller waterways and are

therefore far more prone to clogging than their predecessors. Several boiler

manufacturers insist that the system is thoroughly flushed as a requirement of

their warranty. You will save money on the running costs of your heating system

by anything up to 15%.

Advantages of Powerflushing:

- Cures flow and circulation problems

- Restores system efficiency

- Restores heat output to radiators

- Cleans the whole system, including underfloor pipework

- Removes aggressive water, treatment prevents further corrosion

- Cures or prevents boiler noise

- Powerflushing and descaling in only one visit

- More effective than traditional flushing methods

- Minimises boiler warranty problems

We will fit a MagnaClean after every power flush.

Cost of flush depends upon the size of the system and the number of radiators you have.

Contact us for a quote - the cost will

depend on the size of the system and number of radiators.

Powerflushing is a highly effective cleansing operation which works by pumping water at

a much higher velocity than usual through the heating system to loosen and mobilise

harmful corrosive deposits and to suspend them in the rapidly moving water. The process

is made more effective by specialist cleansing chemicals and an instantaneous flow

reversal device which creates turbulence in the radiators to optimise 'pick up' of debris.

Once loosened, the unwanted debris is purged from the system with clean water. At the

end of the flushing process the system contains fresh clean water and reinstatement of

the system to normal operation takes only minutes.

During the process, radiators are individually flushed without removing or disconnecting.

Indeed the whole process is carried out with minimal disturbance and disruption to the

normal operation of the system, often without the need to disconnect the boiler or

radiators.

The operation takes several hours to complete and once the system has been thoroughly

cleansed, the cleaning agent is neutralised and a corrosion inhibitor added to the system.

If you are upgrading your system with a new high efficiency condensing boiler then power

flushing is essential if you want to realise the published energy efficiency levels of

90% - 94%. Your new boiler cannot be expected to fulfil its potential if your heating

system is full of sludge and scale. Modern boilers have much smaller waterways and are

therefore far more prone to clogging than their predecessors. Several boiler

manufacturers insist that the system is thoroughly flushed as a requirement of

their warranty. You will save money on the running costs of your heating system

by anything up to 15%.

Powerflushing is a highly effective cleansing operation which works by pumping water at

a much higher velocity than usual through the heating system to loosen and mobilise

harmful corrosive deposits and to suspend them in the rapidly moving water. The process

is made more effective by specialist cleansing chemicals and an instantaneous flow

reversal device which creates turbulence in the radiators to optimise 'pick up' of debris.

Once loosened, the unwanted debris is purged from the system with clean water. At the

end of the flushing process the system contains fresh clean water and reinstatement of

the system to normal operation takes only minutes.

During the process, radiators are individually flushed without removing or disconnecting.

Indeed the whole process is carried out with minimal disturbance and disruption to the

normal operation of the system, often without the need to disconnect the boiler or

radiators.

The operation takes several hours to complete and once the system has been thoroughly

cleansed, the cleaning agent is neutralised and a corrosion inhibitor added to the system.

If you are upgrading your system with a new high efficiency condensing boiler then power

flushing is essential if you want to realise the published energy efficiency levels of

90% - 94%. Your new boiler cannot be expected to fulfil its potential if your heating

system is full of sludge and scale. Modern boilers have much smaller waterways and are

therefore far more prone to clogging than their predecessors. Several boiler

manufacturers insist that the system is thoroughly flushed as a requirement of

their warranty. You will save money on the running costs of your heating system

by anything up to 15%.